"Beats Flex-fragment design special edition" is now on sale on Apple's official website

11/03/2022

Container ships are rarely featured on TV news every day. However, there were two topics of container ships in 2021. Do readers remember? The first is the Suez Canal blockade accident that occurred in late March 2021. As a result of the container ship Ever Given, operated by Taiwan's Chang Rong Shipping Co., running aground in the Suez Canal, the passage of other ships was blocked, and a total of about 400 ships were delayed. Two weeks after the accident, things returned to normal. The other is the problem of waiting for container ships to arrive at two major ports on the west coast of the United States, which has become more serious since the fall of 2021. Container cargo movements from Asia to the United States were sluggish in the first half of 2020 due to the spread of COVID-19, but recovered rapidly in the second half of the year due to an increase in stay-at-home demand in the United States. However, the two major ports on the west coast of the United States lacked the capacity to unload containers from container ships, and by the end of September 2021, more than 100 container ships were anchored offshore.

In fact, as the problem of waiting for container ships to enter ports on the west coast of the United States is becoming more serious, major US retailers are taking extremely interesting measures to avoid supply chain interruptions. "Is this also a theme related to supply chains?" It is a perfect story to know the spread of supply chains. First, let's take a look at the changes in consumers who buy goods transported through ports.

Consumers in the United States forced to stay home are buying more things than before. This is the so-called stay-at-home demand. Demand increased for personal computers, tablet terminals and game consoles for telework. In the U.S., where services account for a high percentage of GDP, a change has occurred in which consumers who consume less services than before due to the corona crisis are buying things instead. This change in consumption behavior is conspicuously reflected in the supply chain. For example, not only individual DIY demand but also new housing demand increased, and the supply shortage of building materials caused the price of building materials to soar, causing the "wood shock." Increased demand downstream of the supply chain has led to supply shortages upstream of the supply chain. The impact of the corona crisis on supply chains is not limited to the United States. Most consumer goods purchased in the United States are imported from Asia. In general, consumer goods produced in Asia are loaded onto large container ships, sailed eastward across the Pacific Ocean, landed at the ports of Los Angeles and Long Beach on the southern west coast of the United States, and transported to the United States.

Not only did US consumers' stay-at-home demand lead to an increase in imports, but there was actually another problem. Due to the spread of the new coronavirus infection, the number of dock workers has decreased. As a result, although the number of containers loaded on large container ships has increased, the capacity to unload containers from large container ships that have berthed has decreased, resulting in nearly 100 large container ships waiting to berth offshore.

A and W, well-known US major retailers, took measures to overcome this situation. As import volume increased, it became difficult to procure empty containers, so both companies procured their own containers. In general, container containers used for import and export are borrowed from container shipping companies by shippers and logistics companies.

Furthermore, the two companies have chartered small conventional vessels to avoid the ports of Los Angeles and Long Beach, where offshore congestion continues, and to unload at smaller, less congested ports. The company decided to cover not only containers, but also ships as a means of transportation with its own dedicated resources. The vessels chartered by both companies are conventional vessels, not container vessels. Conventional ships are ships that carry unpackaged bulk cargo such as grain, ore, cement, etc. in their holds, rather than usually carrying containers. Import cargo was transported on the conventional ships with the company's own containers.

Why did Company A and Company W go this far? That would be securing profits during the Christmas sales season, which begins on Black Friday in late November. Due to traffic congestion at ports in the southern part of the US West Coast, the procurement lead time for imported products from China was extended, inventory decreased and shortages increased, resulting in lost sales opportunities. It is presumed that the decision was made to secure the product at the expense of additional costs in order to overcome this. The company's own containers used to carry imported products from China will not be returned to China as empty containers, but will be used for transportation within the United States. Although the amount of investment in fixed assets will temporarily increase, it is presumed that it will be paid for by the increase in business income through the reduction of sales opportunity losses and the reduction of transportation costs in the future.

The above-mentioned procurement of containers and ships exclusively for the shipper company is actually part of the decision-making process of supply chain management (SCM). is. In Japan, the term SCM was often heard in the early 2000s. However, at that time, it was mainly used for software sales and marketing of consulting services, and rather than the entire supply chain, attention was often focused on the specific operations that constitute it. Twenty years later, supply chains have become more complex and uncertain. I think some readers may be wondering, "Is it too late for SCM?", but in fact, I think there is a growing need to learn more about SCM now.

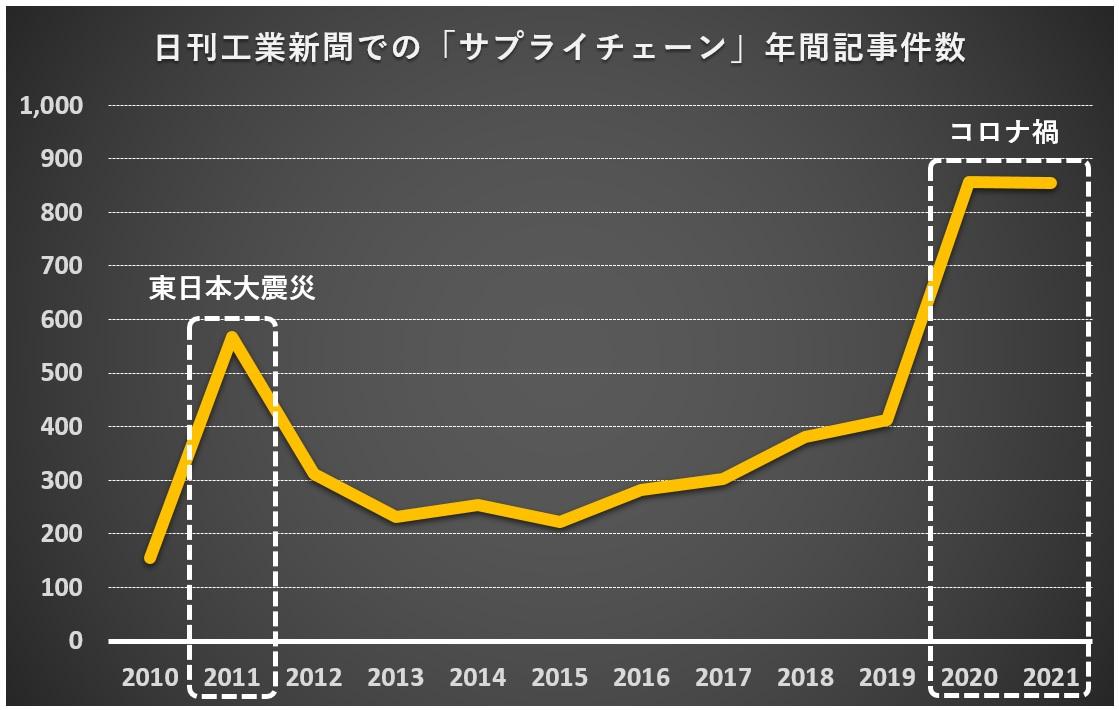

The number of times readers actually touch the word supply chain should be increasing. I counted the number of articles in the Nikkan Kogyo Shimbun in which the term "supply chain" appeared in the last ten years. After a sharp increase to 567 cases in 2011, when the Great East Japan Earthquake struck, the number dropped to an average of 300 cases per year. This is 1.5 times the figure in 2011 when the Great East Japan Earthquake occurred.

Although the recognition of SCM has increased in this way, it is often thought that "SCM deals with a wide range, so it is complicated and difficult to understand". The author, who had such an awareness of the problem, published the "World Standard SCM Textbook" in March 2021 to systematically learn SCM. In this special feature, we will take up topics related to the supply chain that is happening in the world, and will deliver a series of articles that add explanations of important keywords that appear in the "global standard SCM textbook".

SCM is a method for comprehensively reviewing the flow of things, services and decision-making from natural resources to final consumers, and realizing efficiency and optimization of the entire process . This book explains the global standard SCM that is most suitable for companies doing business in the world.

Book title: Learn from the basics! World standard SCM textbook Author name: Keiichi Yamamoto, Tadashi Mizutani, Gyokumoto type: A5 size Total number of pages: 240 pages Price including tax: 2,420 yen Kogyo Shimbun BookstoreNew Switch Original

Container ship that became a hot topic in 2021, unexpected relationship with "nesgomori" (Released on February 15, 2022) Imagining the supply chain from the worsening food crisis Let's try it (Released on February 22, 2022) Optimal points of supply and demand from the perspective of "spam" (Released on March 1, 2022)